When engineer R&D the stucture designing adjustable picture lights,wall lights, adjustable can lights, how important the experience influence the lighting quality?

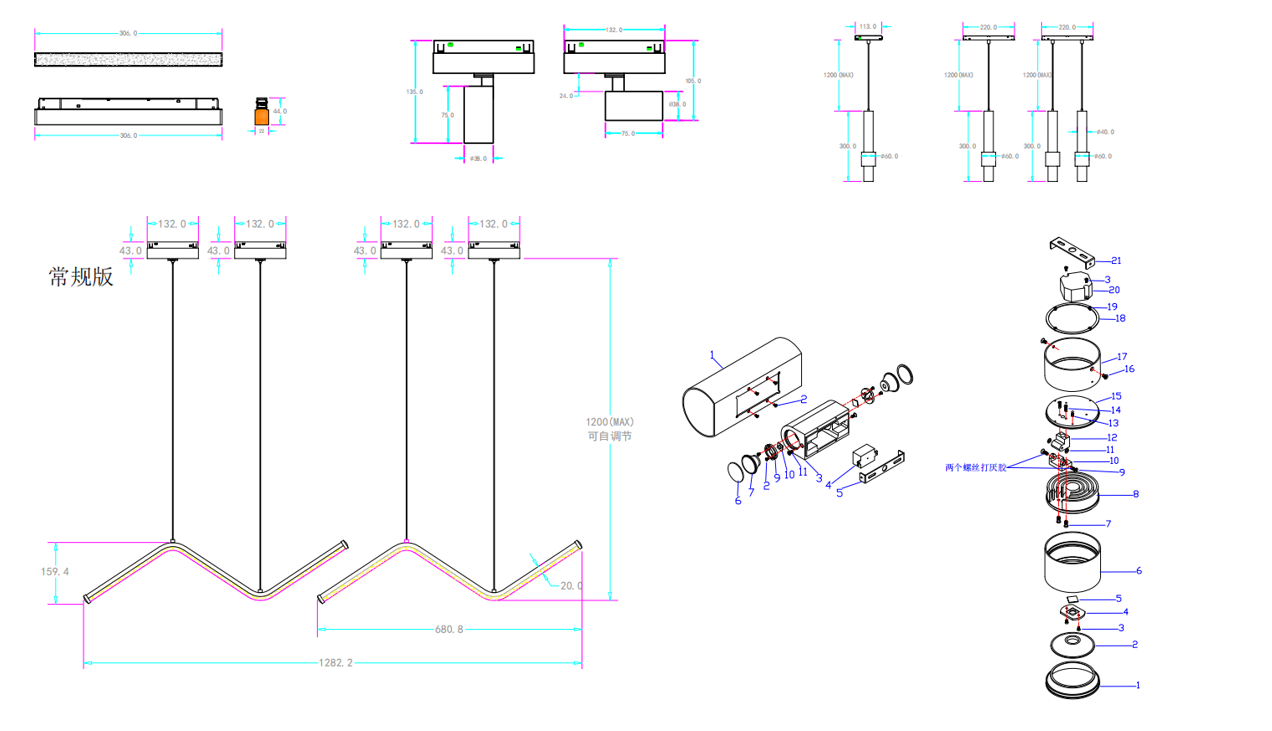

From the drawing of 15W triac dimmable led picture lighting.

As be seen from the figure, it is not easy to do a good job of structural design of spotlights.Our engineers have 15 years of experience in lighting design for architecture lighting projects.

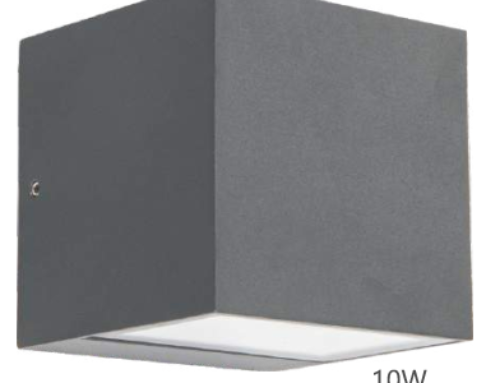

He said that when designing, manufacturing and building structurally adjustable lamps, an anaerobic glue should be added to the screws that link the spotlight shaft. Otherwise, the rotating shaft of the lamp will be loose. In the design of waterproof D shape led wall lamp, the link between the front ring and housing, waterproof silicone ring must be added. Otherwise, IP65 cannot be reached. Remember to point glue at the hole of the ground wire.

According to the design, each adjustable LED Can light contains 21 adjustable parts. Led chip, Drive, lamp body, 38° lens, Countersunk head screw, Meter screw, I-shaped wall lamp mounting plate, Chip bracket, front ring, Aluminum lamp radiator.

A spotlight needs to use at least 5 kinds of screws. Why not use a screw, you may ask? Because different lamps and lanterns structure limits different lamps and lanterns fittings. For example, a 9 watt chip holder and a 15 watt chip holder have different holes, so you need different sizes of screws. As a result, there are often hundreds of screws in the warehouse of the wall lamp manufacturer. You might say that it’s too easy to make wall lamps.

It is easier to know than to do. If you install two screws on the wall lamp shaft by yourself, there is no gap on the shaft, or use strength to insert a gasket into the left and right ends. Inexperienced workers simply can’t do the key lamp structure shaft.

Leave A Comment